Vortex Generator Aircraft - Members DO more Learn more SAVE more - Get more from being a pilot - CLICK HERE

Vortex generators (VGs) do exactly what their name suggests: small wedge-shaped or T-shaped tabs create air vortices in localized parts of aircraft wings.

Vortex Generator Aircraft

For decades, VGs have been used primarily in air transport and military aircraft. After making inroads into general aviation. You can see installed on horizontal stabilizers and on the leading edges of the wings.

Cessna 172 & 175 Vortex Generator Kit By Knots 2u. Cessna Performance Modifications

In multi-engine aircraft, vortex generators improve controllability at slow speeds and reduce stall speed, allowing slower approaches. Slower stall speed can produce a higher takeoff weight, thus improving payload. Similarly, VGs in single-engine aircraft reduce stall speed and improve slow-speed handling.

How do they work? When air flows over an airplane, it attaches to the surface on the wing and produces lift. Separation of the airflow from the upper surface of the wing when the critical angle of attack is exceeded will cause the wing to stall. Vortex generators create their own vortices. These air eddies energize the layer of air immediately above the wing surface and cause the air to remain attached to the airfoil longer, as the angle of attack increases.

Technical editor Jill W. Tallman is a qualified private instrument pilot who owns a Cessna 182Q. Vortex generators, or VGs, the tabs often attached to the tips of airplane wings, play a critical role during takeoff and landing. improve control and reduce installation speed. But in cruise, they do nothing but add drag.

NASA's Glenn Research Center in Ohio and Boeing may have a solution: VGs that are flat during cruise and vertical for takeoff and landing. The key is a unique SMA, short for shape memory alloy, developed at Glenn that functions as a sensor and actuator.

Piper Flyer Association

Normally, SMAs change shape when heated. This SMA, a mixture of nickel, titanium, hafnium and zirconium, does exactly the opposite; it changes shape when it cools. The SMA is formed into a rod about 0.25 centimeters in diameter and lies along the base of the VG, where it acts as a hinge.

As an aircraft climbs to cruising altitude, the air temperature decreases and the SMA rotates, causing the VG to rotate and align with the wing. As the plane descends, the air temperature rises. This causes the SMA to rotate back and the VG to rotate to its vertical position.

In November, NASA and Boeing conducted the first flight tests of what they call Shape Memory Alloy Reconfigurable Technology Vortex Generators, or Smart VGs. They replaced three standard VGs on one wing of Boeing's 777-200 ecoDemonstrator aircraft with Smart VGs.

By the time the ecoDemonstrator reached cruise at about 40,000 feet, the atmospheric temperature had cooled enough, between minus 20 degrees Celsius and minus 60 degrees Celsius, to activate the SMA, causing the Smart VGs to be in the wing . As the ecoDemonstrator descended into warmer temperatures, above 0 degrees Celsius and around 15,000 feet, the SMART VGs began to deploy and lift.

Tailhook Topics: A4d 1 Vortex Generators

"There is no heat application, no batteries, no power source for the vortex generators," says Othmane Benafan, Glenn's lead engineer on the project. "The environment does the trick, and it does it by cooling them down."

Smart VGs could reduce drag on commercial aircraft by 0.2 to 0.5 percent, Boeing and NASA predict. "Over the years, on the fleet, that translates into a large number," says Benafan. If Smart VGs were used on 100 Boeing 777s, over the course of a year they could save 3 million gallons (11.4 million liters) of fuel, the equivalent of taking 3,800 cars off the road for a year , estimates Boeing.

"We are preparing this technology so that it can be used for new airplanes and can be adapted to old airplanes," says F. Tad Calkins, an associate technical partner at Boeing.

For now, this is purely a research effort. Boeing will use data from the ecoDemonstrator test flights, which were completed in late December, to chronicle how the Smart VGs react to various flight conditions and determine whether they meet design requirements. Boeing says it is still too difficult to predict when these might reach any of its plans.

Cessna 182 Vortex Generator Kit By Knots 2u. Cessna Performance Modifications

"These are promising, so I think NASA and Boeing will be optimistic that maybe one day they will find their way to an airplane," says Boeing spokesman Paul McElroy.

A stick made of shape memory alloy at the bottom of a vortex generator acts as a hinge when it cools down, forcing the Smart VG to stay flat while cruising. Credit: Boeing

We're glad you had free access to the digital edition of Aerospace America. If you want to continue reading our publication, you need to join the AIAA or subscribe. Please follow one of the steps below. There I was, at the annual Van's Aircraft Homecoming Fly-In, a delicious local beer in one hand and a handful of raffle tickets in the other. At the end of the night, the raffle tickets were turned into a set of STOLSPEED vortex generators (www.stolspeed.com). So, while I was perfectly happy with the handling qualities of my RV-8, installing Vortex Generators (VGs) seemed like a great opportunity for education and recreation.

The generic list of VG advantages claimed by manufacturers is extensive: lower stall speed, lower takeoff speed, shorter takeoff and landing, improved controllability and safety, easier landing, sharper aileron response, less tendency to drop a wing in a stable, pulp. instead of a stall break, easier and faster stall recovery and more low-speed elevator control, all with little or no loss of cruise speed.

How Stall Strips Work

They are designed to do this by adding turbulence and energy to the boundary layer so that the flow remains attached at higher angles of attack (AoA). The effect of the first order is that the slope of the lift coefficient (C

) vs. AoA remains constant, but stall AoA increases. This stall higher AoA translates into a higher C

Means that lift = weight can be achieved with lower speed (lower stall speed). I set out to test the various VG claims on my specific aircraft.

The CAPTA line made with a Sharpie or electrical tape was used to keep the VGs in a straight line. ION

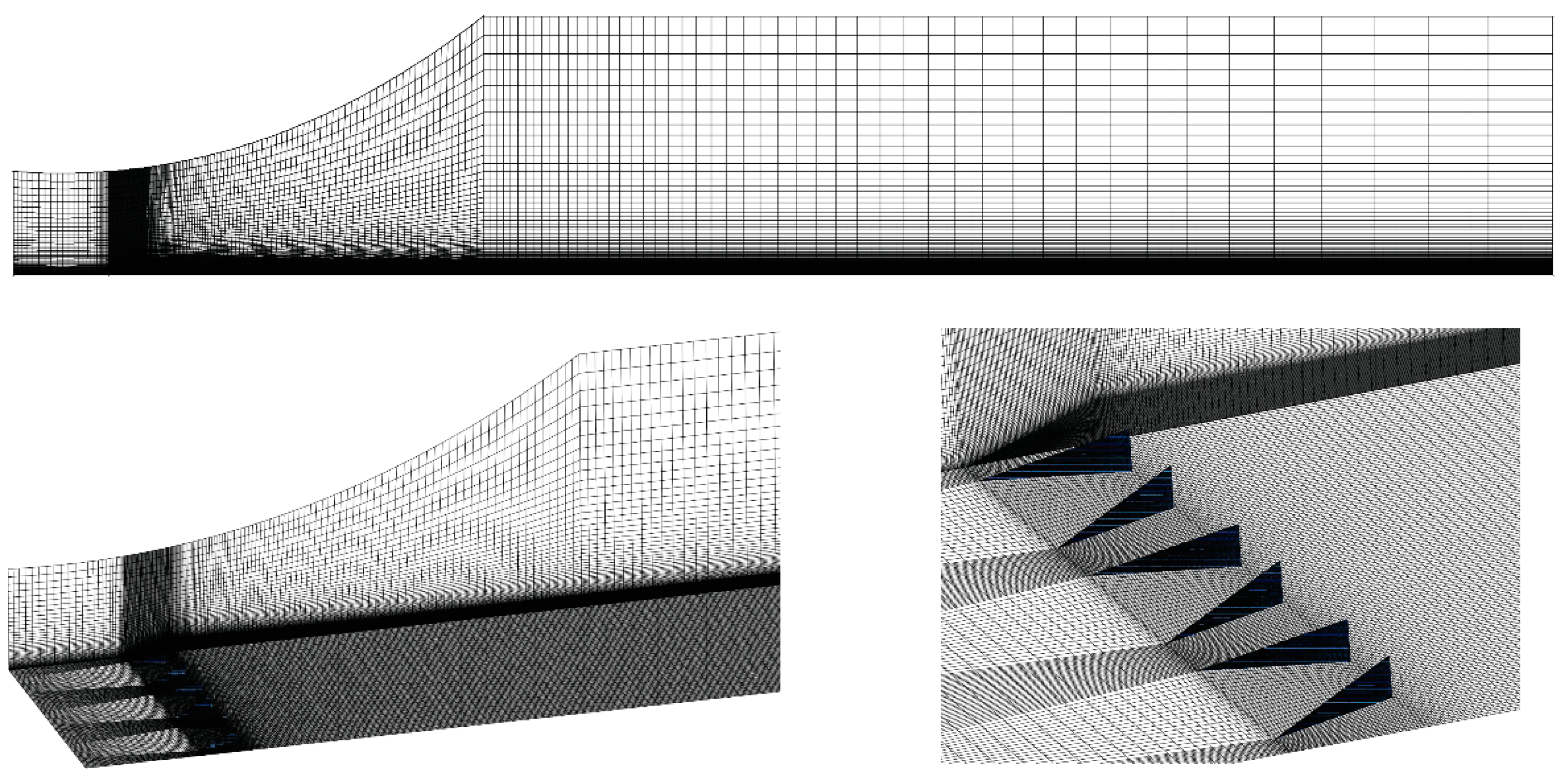

Configurations Of The Vane Type Vortex Generators Under Study

The STOLSPEED VGs are manufactured in Australia and perfectly packaged with laser cut decals and stencils. At the time of writing, the VGs are priced at $97 (wing kit), $65 (tail kit) with $7 postage (worldwide).

Installation instructions were downloaded from the company's website. The VGs were made from a flexible UV resistant polycarbonate. The base was oval in shape, 1 inch long and 0.4 inch wide. They were 0.4 inches tall with a sweep of 27 and had rounded corners. The bases were also slightly curved to allow a better fit to the aerodynamic shape of a wing. If it needs to be attached to a flat surface, they can be easily flattened with a few caps on a sheet of glass that is on a flat surface.

There were 120 VG in the wing kit and 80 in the tail kit. Assembling the VGs was pretty easy and straight forward. Excluding paint, it would be a morning job to apply the VGs to the tail and wing of an RV-8.

The first step was to clean the wing surfaces and the bases of the VGs. Next was to peel the cover from the pre-cut adhesive sheets; an X-Acto knife worked well for this. The VGs were pressed firmly onto the adhesive layer and then removed from the sheet, taking the adhesive layer with them.

Testing Vortex Generators That Get Out Of The Way

Three models were provided: a 1.2 inch (30 mm) horizontal tail gap, a 2.4 inch (60 mm) forward wing aileron gap, and a 3, 5 inches (90 mm) in front of the aileron. flaps. The model puts the VGs at 18 in the chord. The instructions recommend placing the VGs at the bottom of the horizontal tail 4 inches (100 mm) in front of the elevator hinge line. For the wing it was suggested to put 8-10% of the chord from the tip of the tip. The RV-8 wing has a chord of 58.5 inches; I placed the front of the 4.75 inch VGs at the back of the tip where a line of rivets made a convenient mark. This placed the front of the VG at 8.1% and the rear of the VG at 9.8% of the wing chord. A line made with a Sharpie or electrical tape was used to keep the VGs in a straight line.

Fluffs to visualize airflow were made from 6 inch lengths of black wool attached with electrical tape. In rope I attached it to 25%, 50% and 75% on the wing and also in the middle of the ailerons and flaps. Spanwise I attached them every second rib wing.

Once the position of a flake was determined, I attached the flake to the wing with the long end toward the tip. Then I folded the long length on the tape. Finally, I used a second piece of tape

Universal vortex generator, vortex generator, water vortex generator, aircraft vortex, vortex generator subaru, vortex generator wind turbine, vortex generator wrx, vortex generator in aircraft, aircraft generator, subaru oem vortex generator, vortex turbine generator, brz vortex generator

0 Comments